Annilte dawb roj hmab conveyor siv rau txiv laum huab xeeb tshuab thiab Peanut groundnut peeling tshuab

Lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm cov txiv laum huab xeeb yog qhov tseeb yog kev siv cov rotor siab ceev tig tsis nres, los ntawm kev sib tsoo kev sib tsoo, nyob rau hauv qhov kev txiav txim ntawm lub zog ntawm cov txiv laum huab xeeb rau kev puas tsuaj.Cov txiv laum huab xeeb tawg tom qab cov txiv laum huab xeeb tau yooj yim poob tawm, dhau los ntawm cov kiv cua tshuab kom cov txiv laum huab xeeb tau ntim rau hauv ib qho chaw, txiv laum huab xeeb yuav nyob twj ywm.Qee lub tshuab txiv laum huab xeeb muaj lub plhaub thib ob, nyob rau hauv thawj tev tsis huv thaum lub lim yuav raug tso tseg los pab txhawb kev sib tsoo dua.

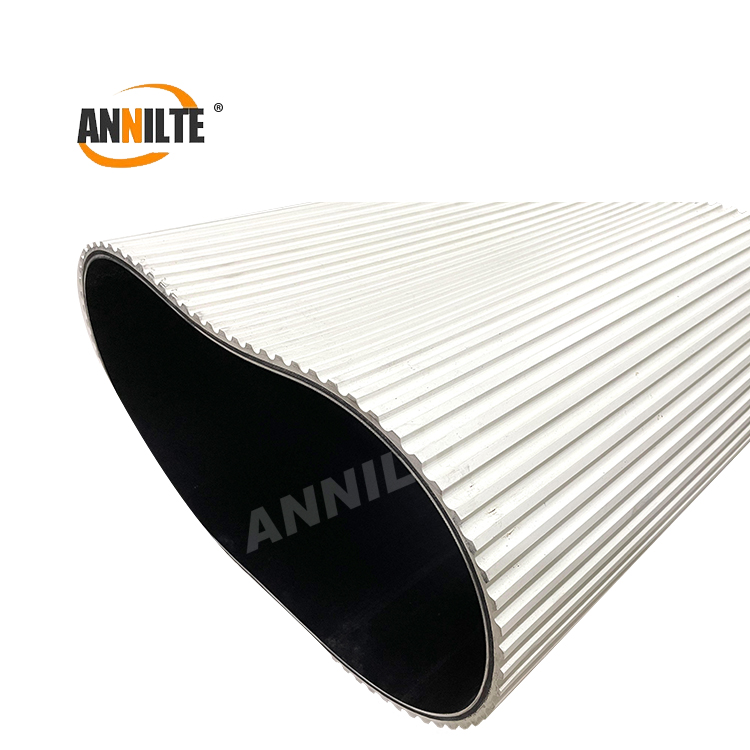

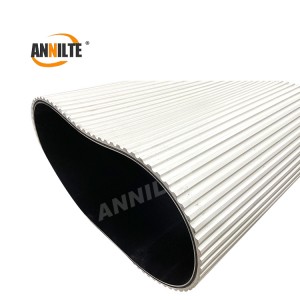

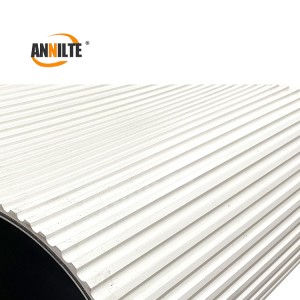

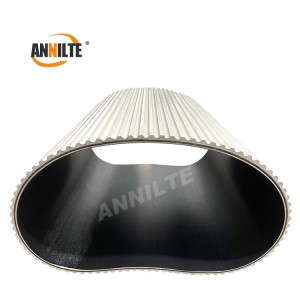

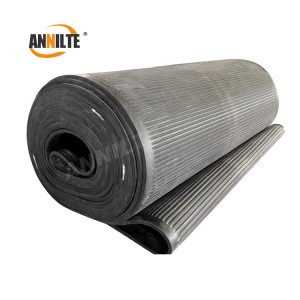

Cov txiv laum huab xeeb lub tshuab siv lub cev yog qhov zoo tshaj plaws-integrated molding kom lub shelling huv si thiab ua haujlwm ntau dua, siv cov hniav tob thiab cov hniav yuav tsum tau tsim raws li curvature ntawm txiv laum huab xeeb, kom cov txheej txheem ntawm shelling tsis yooj yim rau cov txiv laum huab xeeb. , txiv laum huab xeeb tus nqi kuj tuaj yeem txo qis heev;peanut shelling tshuab siv cov khoom siv yog pom zoo kom xaiv cov roj hmab tuaj txawv teb chaws, hnav-tiv taus thiab ruaj khov, tsis yooj yim rau hnub nyoog, piv rau cov tsoos siv, kev pab lub neej ntev dua ib txhia.

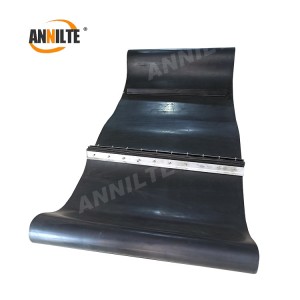

1. Annilte tshwj xeeb tsim apeanut sheller siv, txoj siv lub qhov tob ntawm cov hniav thiab cov hniav raws li cov txiv laum huab xeeb arc tsim, nyob rau hauv lub shelling tsis yooj yim rau cov txiv laum huab xeeb, tuaj yeem txo qhov crushing ntawm 40%;

2. Peanut sheller siv lub cev yog ib daim molding, lub plhaub yog huv si, ntau lawm efficiency;.

3. Cov txiv laum huab xeeb siv cov khoom siv yog ua los ntawm cov roj hmab tuaj txawv teb chaws, hnav-tiv taus, tsis yooj yim rau kev laus, ntau tsoos, kev pab lub neej ntev.

Annilte conveyor siv tsuas yog tsom rau kev tsim cov khoom siv conveyor siv.Kev ua haujlwm.Kev muag khoom, tau muab cov neeg siv khoom zoo siab conveyor siv, raws li cov neeg siv khoom xav tau ntawm cov khoom siv.Dav.Qhov siab.Peb tuaj yeem kho cov khoom, qhov dav, qhov siab, ib puag ncig thiab ntev raws li cov neeg siv khoom xav tau.